Research Center

research & development

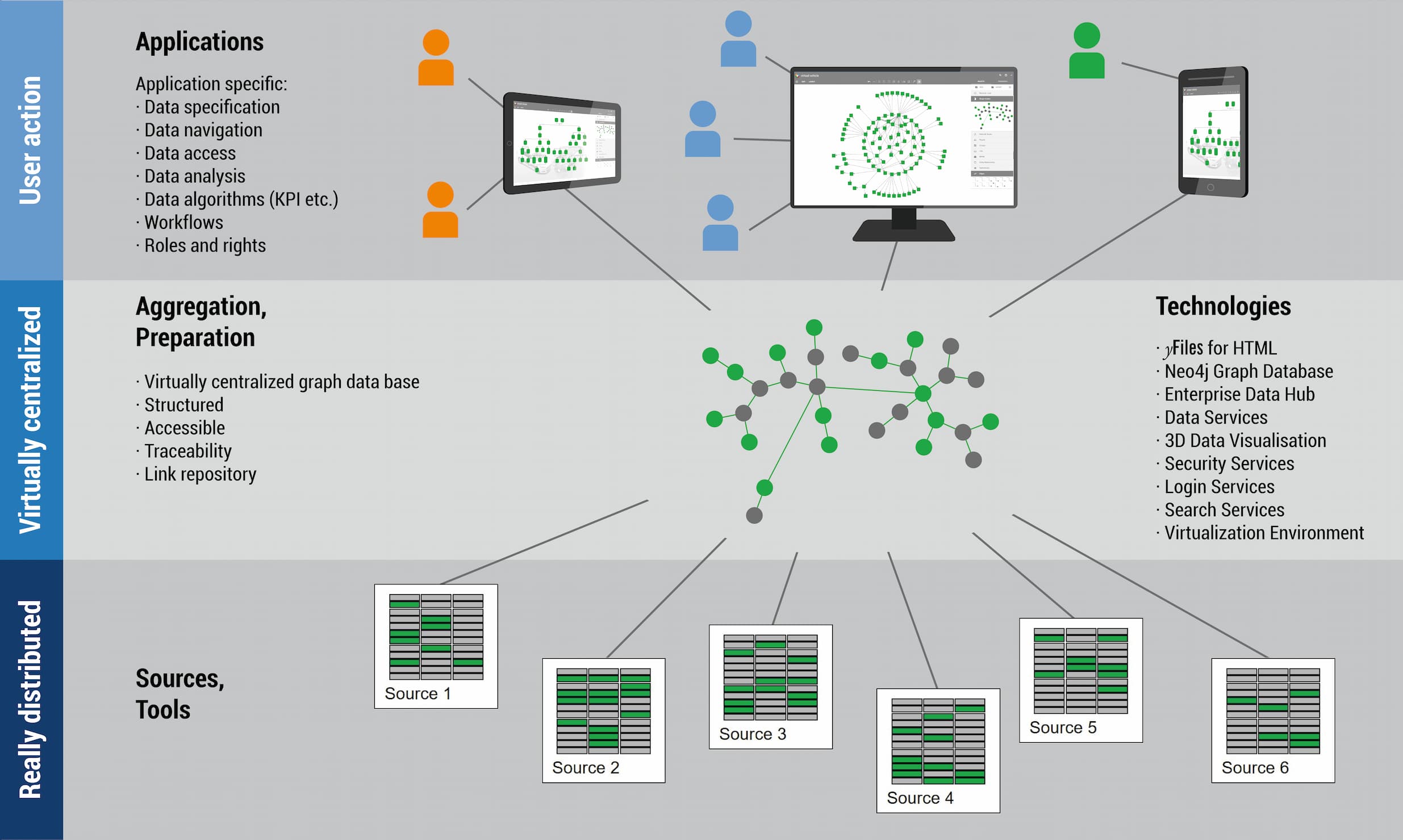

Research & development in the automotive and rail industries is shaped by renowned international project partners with a multitude of data from various sources and structures. In a research project, VIRTUAL VEHICLE develops a prototypical digital decision-making basis: a graph database for data collection and an application for visualizing and navigating the connected data.

How Austrian researchers are rethinking automotive R&D using data visualization and yFiles

New topics like e-mobility and autonomous driving present automotive companies with new challenges, particularly in the area of research and development. For example, the cycles of model development are expected to change. These cycles currently last up to eight years and will become significantly shorter in the future, especially in terms of software and hardware.

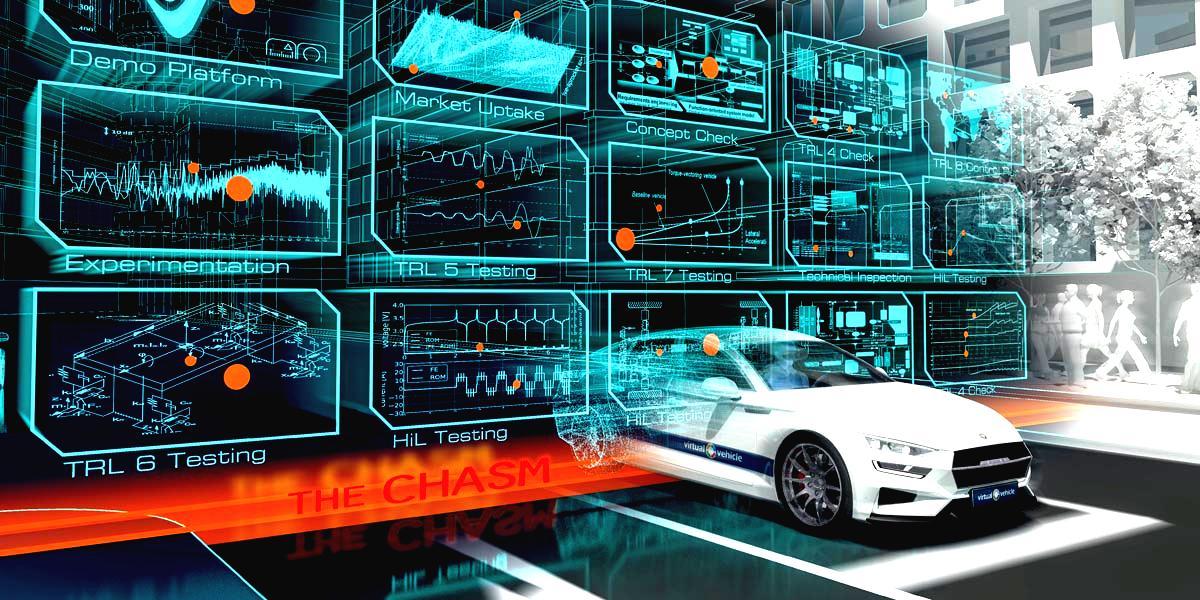

Source: VIRTUAL VEHICLE

Source: VIRTUAL VEHICLETo meet these future demands, research & development is rapidly moving in the direction of virtualization and digitization – away from classical experiments on prototypes, and towards numerical methods. This evolution requires new development environments with agile processes and the appropriate methods and tools. For this reason, the Efficient Development division of VIRTUAL VEHICLE Research Center in Graz, Austria - one of the leading research centers for automotive and rail industries - focuses on a functional system view, orchestration of complex product verification, and advanced information and process management. VIRTUAL VEHICLE, one of the leading R&D centers for the automotive and rail industries, is based in Graz, Austria.

Future Engineering Lab

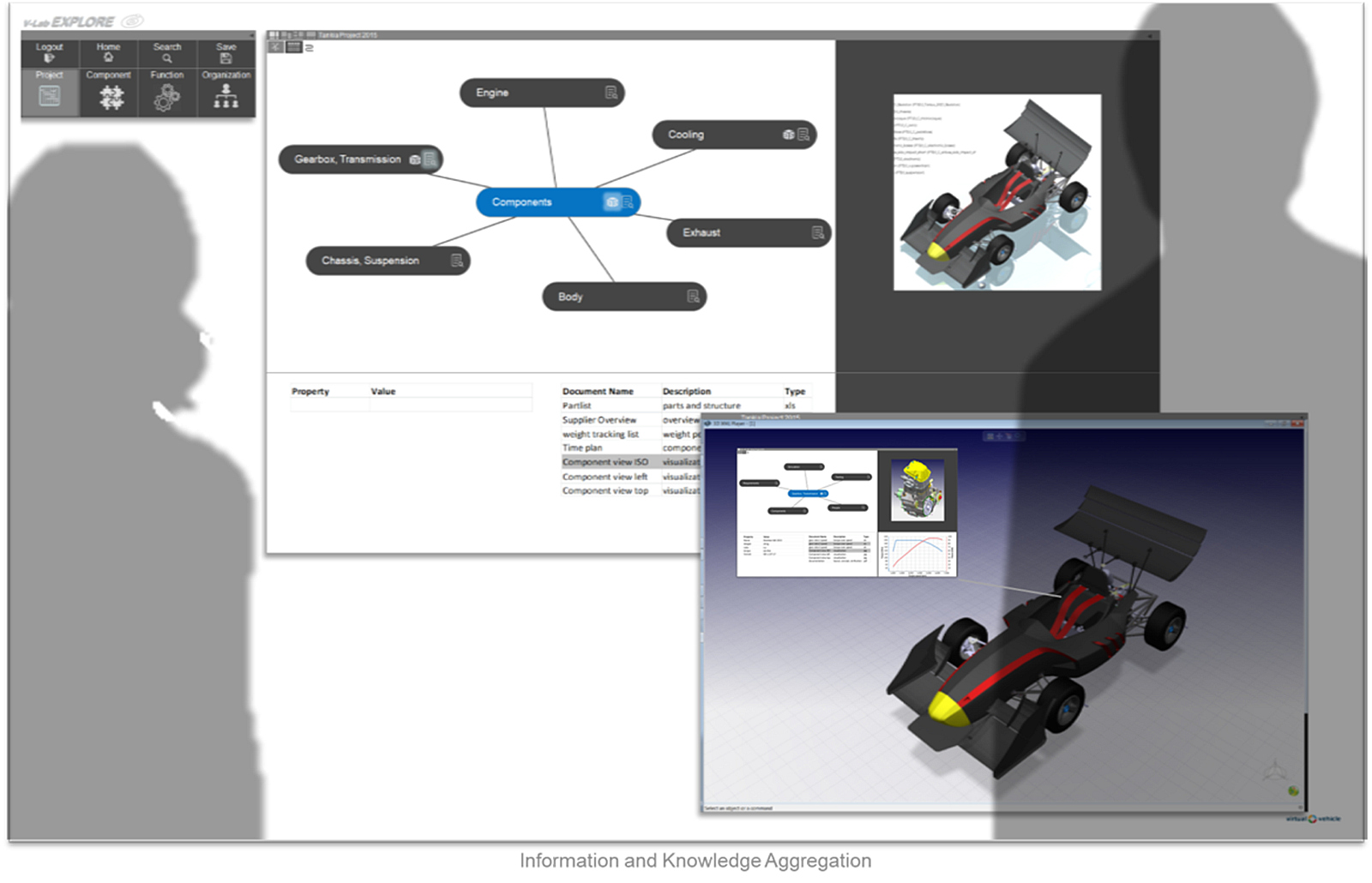

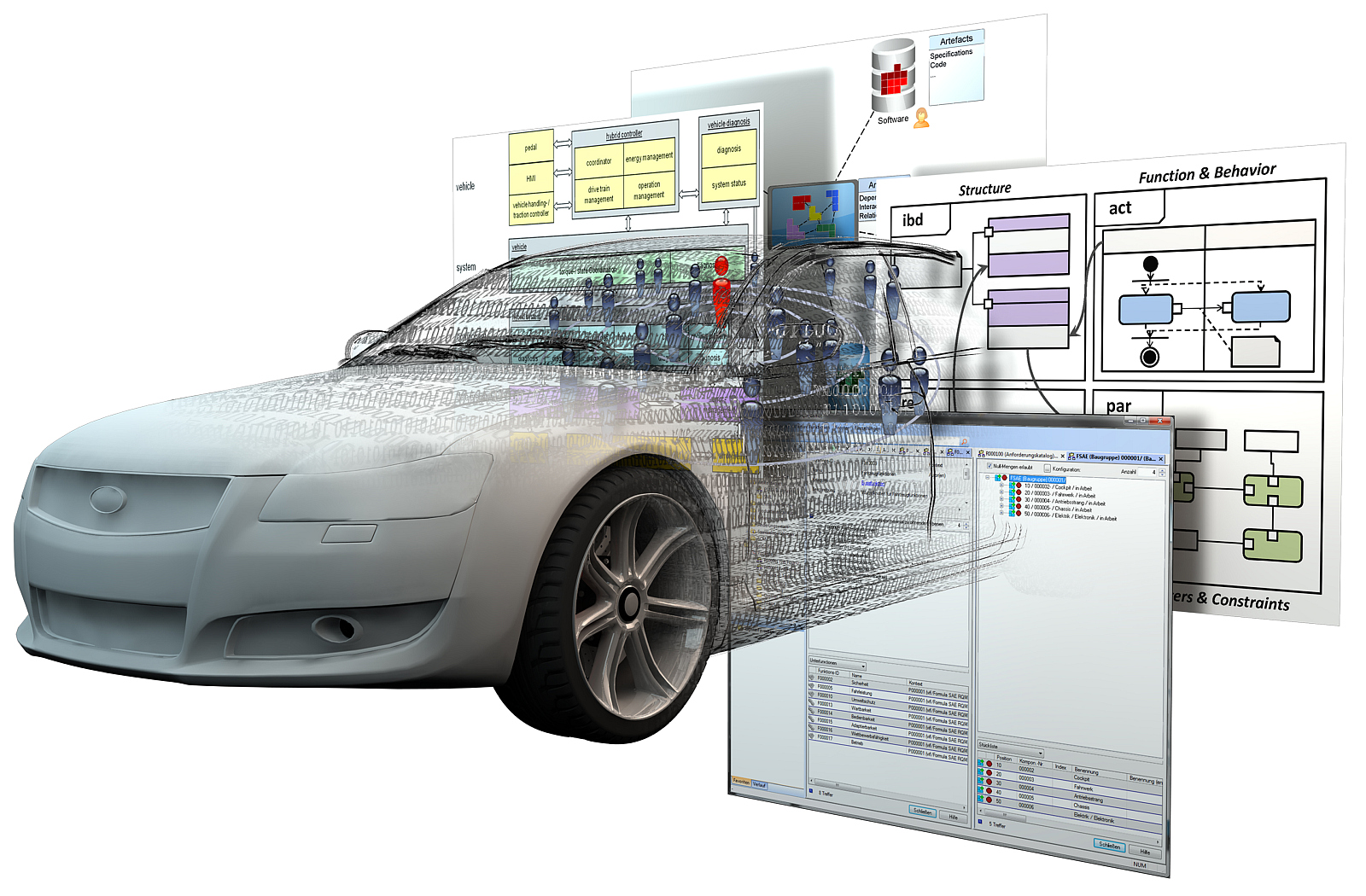

The Future Engineering Lab project team is working with renowned project partners from the automotive and rail industries to develop a prototype implementation of future data provision and consistency in engineering, along the product lifecycle. Their approach is to collect the heterogeneous data sources, and then develop aggregating and view-based access to them. By virtually merging the metadata in a graph database, the team frees itself from predefined data structures (as is common in relational database systems). As a result, they can concentrate on the relationships between the data, and integrate additional data sources as needed. The researchers develop a web application whose core is data visualization. An interactive graph makes it easy to navigate through the data and serves as a digital decision-making basis for development engineers. The data is stored in native graph format in a NEO4j database.

Visualizing the data

The requirements for the visualization solution were: potential future integration into other tools and platforms, intuitive visualization of large linked data sets, the option of expanding and collapsing data points, suitable structuring of the visualization, and a high degree of freedom in realizing the project and designing user interactions. After a lengthy evaluation of commercial as well as freely available visualization tools, the decision was made in favor of yFiles for HTML, by yWorks GmbH.

“The flexibility in designing our own application, as well as the many existing, relevant implementation examples led to our decision to use yFiles.”Dr. Bernd Fachbach, project lead

The developed test model serves as a prototype of future data provision and consistency in engineering, along the product lifecycle. The prototype is intended as a future-proof model: a web application that allows exploration and navigation in context-based engineering information. Initial results will be published in summer 2019.

VIRTUAL VEHICLE | Kompetenzzentrum – Das Virtuelle Fahrzeug Forschungsgesellschaft mbH

VIRTUAL VEHICLE is a leading international research and development center for the automotive and rail industries, located in Graz, Austria. The center focuses on the consistent virtualization of vehicle development. An essential element is the linking of numerical simulations and hardware testing, which ensures a comprehensive hardware-software system design.

VIRTUAL VEHICLE’s international partner network consists of:

80+ international industrial partners

40+ international scientific institutions (including TU Graz, TU Berlin, Fraunhofer)

VIRTUAL VEHICLE is the largest COMET-funded research center and is also active in over 30 EU projects. In addition, VIRTUAL VEHICLE offers a broad portfolio of contract research for vehicle development.

PWC Studie Automotive Eascy

https://www.pwc.de/de/automobilindustrie/pwc_automotive_eascy-studie.pdf